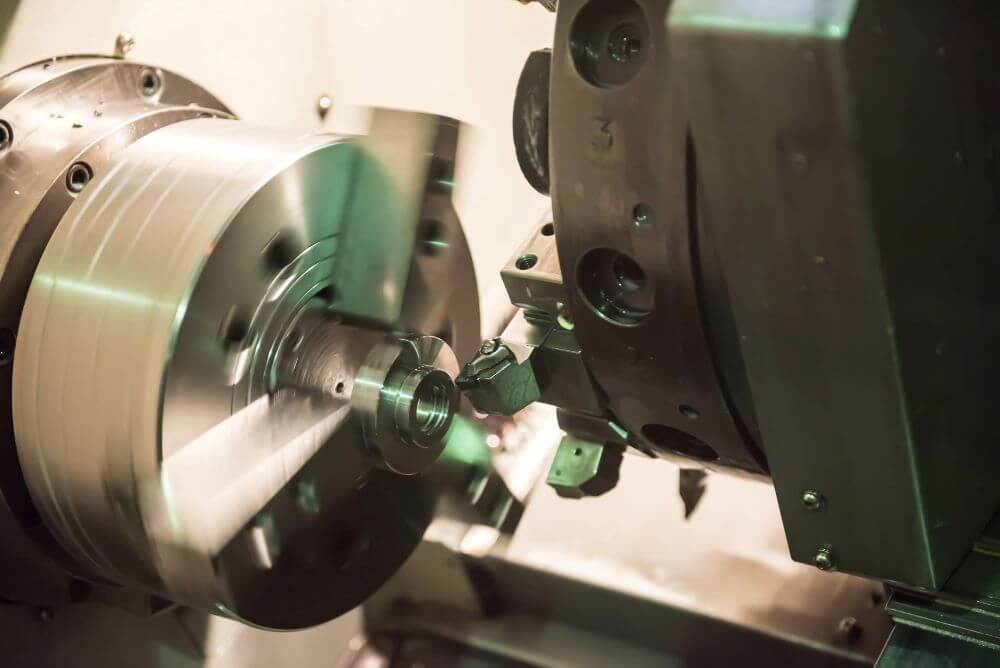

Manufacturing has evolved dramatically over the past few decades, and CNC aluminum parts have become the backbone of countless industries. From aerospace components to consumer electronics, aluminum machining offers an unbeatable combination of versatility, cost-effectiveness, and reliability that keeps engineers coming back for more.

The appeal of aluminum in CNC machining stems from its unique properties. This lightweight metal machines beautifully, produces excellent surface finishes, and resists corrosion naturally. When you combine these characteristics with modern CNC technology, you get a manufacturing process that delivers consistent results at scale.

Why Aluminum Dominates CNC Machining

Aluminum stands out among machining materials for several compelling reasons. Its soft, malleable nature allows cutting tools to move through it with minimal resistance, reducing wear on expensive tooling. This translates directly into lower production costs and faster cycle times.

The metal’s thermal conductivity also works in your favor during machining. Heat dissipates quickly, preventing the workpiece from warping or the cutting tool from overheating. This thermal stability means you can push speeds and feeds higher than with many other materials, boosting productivity without sacrificing precision.

Weight considerations make aluminum particularly attractive for transportation applications. Aircraft manufacturers rely heavily on CNC aluminum parts because every pound saved translates into fuel efficiency gains. Similarly, automotive engineers use aluminum components to meet increasingly strict fuel economy standards while maintaining structural integrity.

The corrosion resistance of aluminum adds another layer of value. Unlike steel, aluminum forms a protective oxide layer when exposed to air. This natural barrier prevents further oxidation, eliminating the need for additional coatings in many applications. The result is parts that maintain their appearance and functionality longer, reducing replacement costs and downtime.

Prototyping Advantages with Aluminum CNC

Prototyping represents one of aluminum’s strongest applications in CNC machining. The material’s forgiving nature allows rapid design iterations without breaking the budget. Engineers can test form, fit, and function quickly, making design changes on the fly.

Speed matters enormously in product development cycles. CNC aluminum parts can often be produced in hours rather than days or weeks required for other manufacturing methods. This rapid turnaround enables multiple prototype iterations within tight development schedules, giving design teams the flexibility they need to optimize products before committing to production tooling.

The dimensional accuracy achievable with aluminum CNC machining closely matches what you’ll get in production. This means prototype testing provides reliable data for making final design decisions. Unlike 3D printed prototypes that may have different material properties, machined aluminum prototypes behave like the actual production parts.

Cost control during prototyping becomes much more manageable with aluminum. The material itself is relatively inexpensive, and the excellent machinability keeps cycle times short. When you factor in the ability to use the same fixtures and tooling across multiple prototype revisions, the economics become even more favorable.

Production Scalability and Cost Management

Transitioning from prototype to production often presents challenges, but CNC aluminum parts offer remarkable scalability. The same programs, tooling, and setups used for prototyping can often be adapted directly for production runs, minimizing transition costs and time.

Volume economics work particularly well with aluminum machining. As quantities increase, you can optimize tooling, fixturing, and programming to drive down per-piece costs. The material’s consistency means less variation between parts, reducing quality control requirements and associated costs.

Setup reduction strategies become highly effective with aluminum’s predictable machining characteristics. Multiple parts can often be machined in single setups, and the material’s stability allows for longer unmanned running times. This efficiency directly impacts your bottom line by maximizing machine utilization.

Tool life optimization represents another cost advantage. Aluminum’s gentle nature on cutting tools means you can achieve thousands of parts from a single tool set under the right conditions. When you factor in the time saved from fewer tool changes and the reduced tooling costs, the economics become compelling.

Quality Considerations and Surface Finishes

Quality control with CNC aluminum parts offers distinct advantages over many other materials. The metal’s homogeneous structure eliminates many variables that can affect dimensional accuracy. Internal stresses are minimal, so parts maintain their shape and dimensions over time.

Surface finish capabilities with aluminum are exceptional. The material can achieve mirror-like finishes directly from machining operations, often eliminating secondary finishing processes. This direct-to-finish capability reduces handling, processing time, and associated costs while maintaining tight tolerances.

Anodizing compatibility adds another quality dimension. Aluminum parts can be anodized for enhanced corrosion resistance, improved wear characteristics, or aesthetic purposes. The anodizing process actually improves dimensional stability by creating a hard, protective surface layer.

Inspection and measurement processes benefit from aluminum’s thermal stability. The material doesn’t expand or contract significantly with temperature changes during measurement, providing more reliable dimensional data. This stability reduces measurement uncertainty and improves overall quality assurance processes.

Material Grades and Selection Strategy

Choosing the right aluminum alloy significantly impacts both cost and performance. The 6061 alloy offers an excellent balance of machinability, strength, and cost for general applications. Its widespread availability keeps material costs low while providing good mechanical properties for most applications.

For applications requiring higher strength, 7075 aluminum provides exceptional performance but at a higher material cost. The improved strength-to-weight ratio often justifies the additional expense in aerospace and high-performance applications where weight savings translate directly into operational benefits.

The 2024 alloy serves specialized applications requiring high strength and excellent fatigue resistance. While more expensive and challenging to machine than 6061, it delivers performance characteristics that justify the additional costs in demanding applications.

Material availability affects both cost and lead times. Common alloys like 6061 are readily available in various forms and sizes, keeping costs low and delivery times short. Specialty alloys may require longer lead times and carry premium pricing, factors that should be considered during the design phase.

Machining Strategy Optimization

Toolpath optimization for aluminum requires understanding the material’s unique characteristics. Conventional milling often works better than climb milling for achieving superior surface finishes. The material’s tendency to work harden slightly under load means consistent chip removal is crucial for maintaining surface quality.

Coolant strategies vary depending on the specific operation and alloy. Some aluminum grades machine beautifully dry, while others benefit from flood coolant or minimum quantity lubrication. Understanding these nuances helps optimize both tool life and surface finish while controlling machining costs.

Workholding solutions for aluminum must account for the material’s relatively low stiffness compared to steel. Proper support prevents deflection and chatter, which can compromise both dimensional accuracy and surface finish. Investment in appropriate fixturing pays dividends in reduced scrap rates and improved cycle times.

Chip evacuation becomes critical with aluminum’s tendency to produce long, stringy chips at certain cutting parameters. Proper chip breaking and removal prevent chip rewelding and surface scratching, maintaining the quality standards that make CNC aluminum parts so attractive.

Overall Reflection

CNC aluminum parts represent a sweet spot in modern manufacturing where cost-effectiveness meets high quality. The material’s excellent machinability, combined with its favorable physical properties, creates opportunities for significant cost savings without compromising performance standards.

Success with aluminum CNC machining requires understanding the material’s unique characteristics and optimizing processes accordingly. When done correctly, the combination of fast cycle times, excellent surface finishes, and predictable results creates a compelling value proposition for both prototyping and production applications.

The versatility of aluminum continues to expand manufacturing possibilities across industries. As CNC technology advances and aluminum alloys improve, the cost-quality relationship will likely become even more favorable, solidifying aluminum’s position as a premier machining material for years to come.